April 2012 nz metal roof and wall cladding code of practice table of contents v 2 2 page 3 table of contents 1 1 0 table of contents 2 0p erformance 3 0 construction load 4 0 d esign 5 0f lashings 6 0p enetrations 7 0i nstallation 8 0 roof drainage 9 0 plastic roof lighting 10 0 pressed metal tiles.

Apron roof flashing nz.

New zealand metal roofing manufacturers inc.

Flashings near the edges of roofs or walls can be subjected to suction or negative wind loads that can be greater than other positive imposed loads.

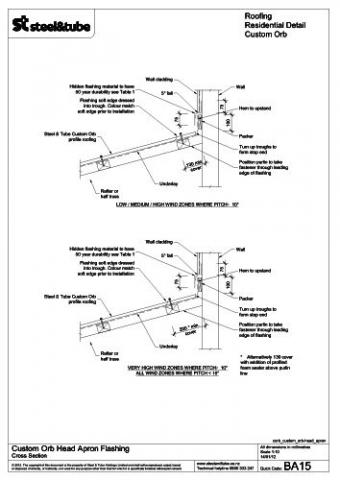

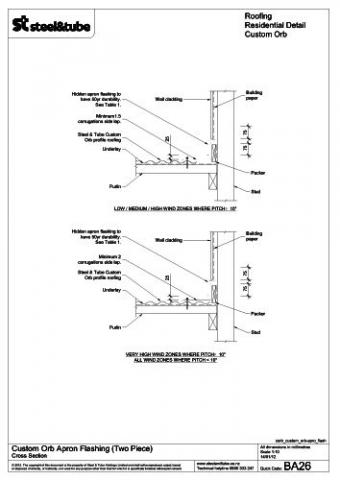

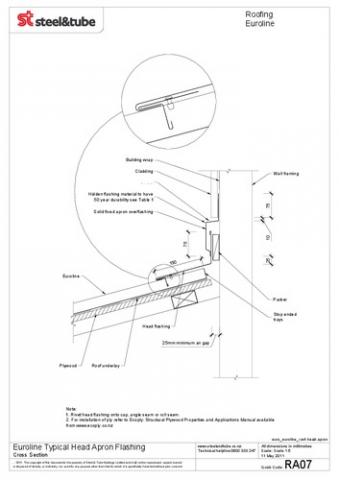

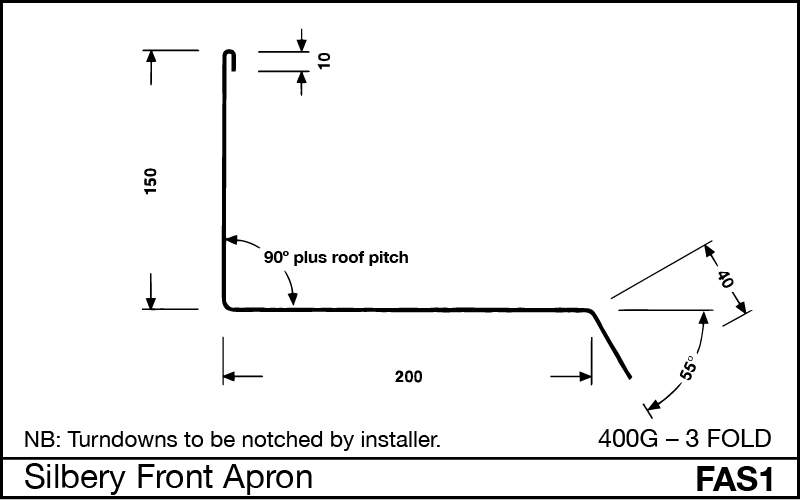

Figure 1 apron flashing at roof wall junction horizontal flashing.

E2 as1 requires eaves flashing see figure 7 to be installed with long run profiled metal roofing in vh or eh wind zones where the roof slope is 10 or less and the soffit width is 100 mm or less from the cladding.

As drawn the details do not close off the cavity to water entry blown by wind up the slope of the roof on the apron flashing.

The fabricated corner flashing needs a stop end with the stop end 35 mm minimum high up to the bottom of the cladding then cut back to also close off the cavity up to the top of the flashings.

Covid 19 update to customers.

Dektite flashings are a range of epdm or silicone polymer flashings distributed in nz by dlm and manufactured by deks industries pty ltd australia.

The range delivers a wide choice of specifically designed innovative products to prevent the ingress of water and dust at service pipes flues and ducts that penetrate roofs or walls.

Check out our wide range of flashings from brands you know trust.

Note these flashings do not have corrugations in them.

All roof cladding located at the join except gutters require a flashing fastened on both sides of the join.

Flashing at a change of pitch for eh wind zone is outside the scope of e2 as1 and must be treated as an alternative method.

The minimum cover for the lower roof pitch is as for an apron flashing the flashing must be extended at least 250 mm under the higher roof pitch e2 as1 figure 44.

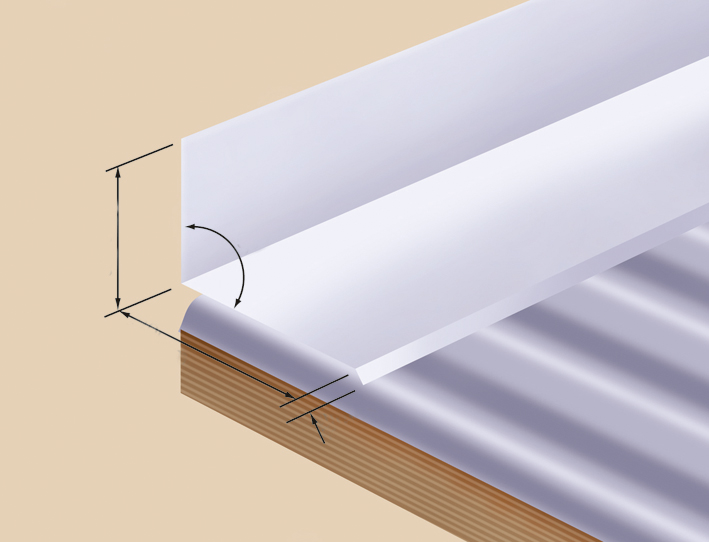

A flashing which runs horizontal to the corrugate and has a vertical upstand with a 200mm flap folded at the same pitch of the roof with a soft edge at the bottom.

I 2 o i build supplement flashings 23.

They are essentially flat strips of polycarbonate bent into the various profiles.

Raked metal apron flashings must have tapered stop ends to the lower end of the flashing to divert water away from the back of the upstand and into the gutter and have a 5 minimum cross fall see roof to wall junction in build 160.